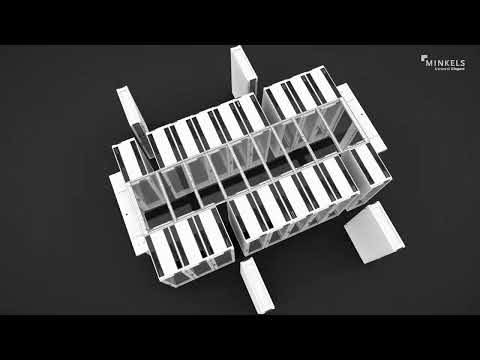

Chilled Water Coolers

CW Solutions offer higher cooling capacities to face the most demanding applications. These prove to be more energy efficient when the heat load of the containment goes beyond 100kW.

Nexpand CW40 & CW60

- Cooling equipment is close to the heat source

- Shortening the airflow path, thereby decreasing power consumption of the fan units

- Providing a fast, dynamic response of the coolers to changing heat densities.

- Sustainability is at the forefront of the Nexpand row-based cooling solutions.

Top and Bottom Piping Connections

Connections for piping may enter the cooler from either the top or bottom of the unit. To facilitate this, all versions of the CW40 and CW60 accommodate top and bottom piping entry into the cooler. Also included on top and bottom are cable throughputs for connectivity, power and condensate discharge.

Display

The display is placed at eyesight and is seamlessly integrated in the perforated or blind doors. The latter depends on the chosen cooling configuration. It enables reading the most important values for the cooling performance, such as cold and hot aisle temperatures as well as fan speed and the degree of opening of the water valve. The standard display comes with buttons to navigate through the controller software. The display can be upgraded with a touch screen display for a more premium look and feel of the cooling solution.

Advanced Control and Carel Monitoring

To make sure you always know how the cooler is performing these are equipped with remote monitoring possibilities. Modbus RTU is standardly available as well as digital inand outputs. This will allow you to monitor and control a vast number of businesscritical parameters. Please review the list of options for more possibilities regarding remote monitoring & control.

Hot Swappable Fans

The coolers are equipped with hot-swappable fans. To minimize possible downtime due to fan failure, this feature enables swift and safe replacement of the fans. The unit does not need to be turned off to replace the fan(s), so the issue of a faulty fan can be resolved in a matter of minutes.

EC Fan Technology

The fans are all equipped with EC fan technology. The benefits are an extended lifetime and a significant increase in the energy efficiency of the unit. Also, the fans are equipped with emergency speed functions. This means that even with controller downtime the fans are still running.

Nexpand Frame

The cooling technology is fully integrated in a Nexpand frame. In this way you benefit from the same look & feel throughout your white space solution. Baying to adjacent cabinets is done in the exact same way as baying IT cabinets.

Security

As the Coolers are based on the Nexpand platform the front and rear closure is the same as with the standard IT cabinets. Apart from keeping the same look & feel it also enables the use of the same mechanical locking possibilities as with our range of IT cabinets. With this we ensure the highest level of security possible.

Hydrophilic Coils and Integrated Float Switch

As a standard all our models feature evaporators with Hydrophilic treatment. This special coating facilitates the condensate discharge towards the drip tray which is placed below the evaporator. As an extra security feature each cooler is standardly equipped with a float switch installed in the drip tray. The purpose of the float switch is to sense when a maximum level of condensate is reached.

Dual Power Feed

To ensure your cooling system remains up and running even after power outage of the main feed we have standardly integrated a dual power feed that automatically switches to the redundant power feed.

Slide-out Electrical Box

The electrical box is designed to take up as little space as possible without interfering with air distribution over the whole working height of the unit. To achieve this, without affecting accessibility during the initial start-up and unscheduled maintenance operations, a sliding drawer version has been created. This design also prevents tangling of the wiring whilst sliding.

Condensate Pump

When condensate discharge via gravity is not possible because of a concrete floor or other limitations, a condensate pump can be chosen. This will get rid of any condensate that may occur from the drip tray where it is collected from the heat exchanger.

Touch screen

To upgrade your cooler for a more user friendly and high-tech feeling a touch screen display can be chosen. It utilizes the same cut-out in the door as the standard display so even retrofit upgrades are an easy job.

Advanced Monitoring

When monitoring through other communications protocols is a need, we can support this by upgrading with the pCOWeb card. It features communication with SNMPv2c, BACNET, Modbus over TCP/ IP and it is equipped with an integrated webserver

Base set 100mm

When there are requirements when it comes to piping work and/or cabling underneath the cooler, a base-set which extends the height with 100mm can be deployed. The base-set is also available for our standard range of IT cabinets so the entire set-up including cooling can be perfectly aligned and have the same look & feel.

3-Way Valve

As a standard 2-way valves are integrated in the hydraulics circuit of the coolers. The 2-way valves are meant for cooling infrastructures with variable flow. As an alternative, in the case of systems with a fixed flow, we can offer our hydraulics circuit with a 3-way valve.

Transport Tool

Safety and ease of transportation are important factors especially in the initial stages of the cooler deployment. To ensure a safe placement of the coolers which, due to their weight and form factor, have a risk of tipping over, we have developed a dedicated transport tool. The tool is easy to mount and remove and it also improves the maneuverability of the cooler in the white space area.

Filterset G4 + Differential Pressure Sensor

To collect potential dust and particles we can offer a filter set class G4. A differential pressure sensor will detect at a pre-defined threshold when it reaches the maximum pressure. This will indicate a clogged filter so it can be replaced at the next service interval or prior to that.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand